An oil-lubricated stern shaft seal is a critical component of a vessel’s propulsion system, specifically designed to create a watertight and oil-tight barrier where the propeller shaft exits the hull. Its primary functions are to prevent seawater from entering the stern tube and to prevent lubricating oil from leaking into the marine environment.1

Here is a summary of the components, function, and spare parts for an oil lubrication stern shaft seal.

Core Components and Function

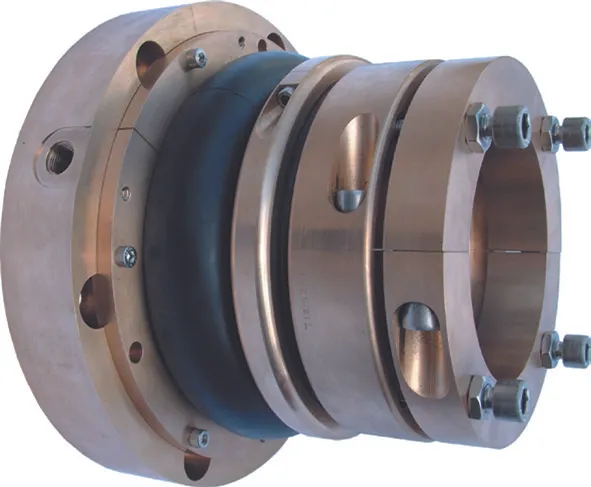

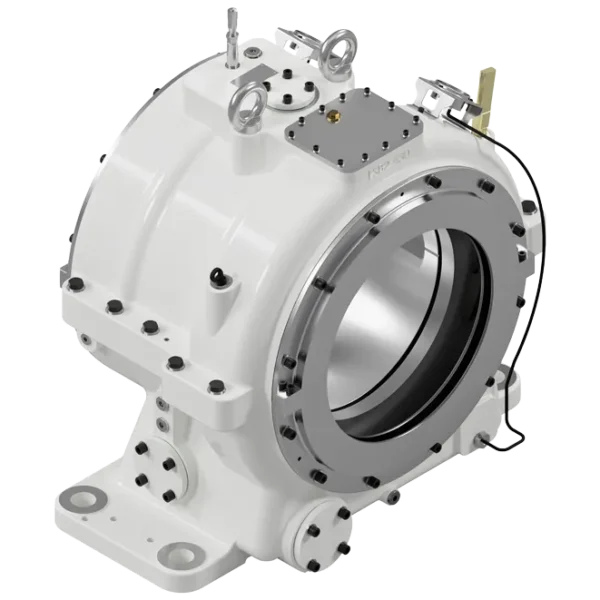

An oil-lubricated stern shaft seal system typically consists of multiple sealing rings housed within a single casing, along with a dedicated lubrication system.2

- Seal Rings (Lip Seals): The main working parts of the seal.3 These are flexible, spring-loaded rings (often made of a special elastomer) that make a tight, rotating contact with a hard, corrosion-resistant liner on the shaft. There are usually two sets of seals:4

- Aft Seals (Water side): Face outwards to prevent seawater from entering.

- Forward Seals (Oil side): Face inwards to prevent lubricating oil from leaking into the vessel or the sea.

- Seal Housing: The robust metal casing that holds the seal rings in place and bolts securely to the stern tube flange.

- Shaft Liner: A smooth, durable sleeve fitted over the propeller shaft. The seal rings run against this liner, which protects the main shaft from wear.

- Lubrication System: A separate oil circulation system is used to lubricate and cool the seals and stern tube bearings. It includes an oil header tank (a gravity-fed tank located above the waterline to maintain a positive oil pressure) and a sight glass to monitor the oil level.

The system works by maintaining a positive oil pressure that is slightly higher than the external seawater pressure, ensuring that any small leakage is of lubricating oil outwards rather than seawater inwards.

Common Spare Parts

Maintenance of stern shaft seals is essential to prevent both environmental pollution and catastrophic flooding. The following spare parts are crucial for service and emergency repairs:

- Seal Kits: This is the most important and frequently required spare part. A complete seal kit contains new lip seals (aft and forward), O-rings, and other gaskets and bolts needed for a seal change.

- Shaft Liner: Also known as the chrome sleeve or wearing sleeve. This part is subject to wear from the friction of the lip seals and must be replaced if a new seal kit cannot make a proper contact surface.

- Oil Pump & Filters: Spares for the lubrication system, including pump parts and filters for the stern tube oil.

- Emergency Seals: Some systems are fitted with an emergency or inflatable seal that can be activated to provide a temporary seal, allowing the crew to make repairs or a seal change without dry-docking. Spares for this system are vital.

- Coupling Bolts & Gaskets: Spare bolts and gaskets for the stern tube flange and propeller nut, in case they need to be removed.

- Bearings: While less frequent, spares for the stern tube bearings (e.g., polymer bearings) are needed for major overhauls.

Key Manufacturers

The stern shaft seal market is dominated by a few specialized, high-quality manufacturers:

- Wärtsilä: A global leader with products like the Wärtsilä Enviro-Seal, known for its focus on environmental protection and reliability.

- Thordon Bearings: A manufacturer of both specialized polymer stern tube bearings and shaft sealing systems.

- SKF Marine: A major supplier of shaft alignment and sealing systems, including their Simplex-Compact seals.5

- EagleBurgmann: A well-known manufacturer of mechanical seals, including those for marine applications.

- IHC Lagersmit: Specializes in stern tube seals and bearings.

Regular monitoring of the header tank oil level and periodic inspections during dry-docking are essential to ensure the seal’s integrity and prevent both environmental damage and vessel downtime.

We offer an extensive range of marine engine brands and their associated spare parts, providing comprehensive solutions for both main propulsion and auxiliary power needs across diverse vessel types. Our supply capability covers various generations and models, ensuring support for a wide array of marine applications.

Featured Brands and Engine Series/Models:

SULZER:

- Two-Stroke Engines:

- RD/RND Series: RD68, RND76, RND76M, RND90, RND90M (Classic large-bore, low-speed engines, still in operation).

- RLA/RLB Series: RLA(B)56, RLA(B)66, RLA(B)76, RLB90 (Developed two-stroke designs).

- RTA/RT-Flex Series: RTA38, RTA48(T), RTA52, RTA58, RTA62, RTA72, RTA76, RTA84, RTA84M, RTA84C, RTA96 (Modern, fuel-efficient, electronically controlled two-stroke engines).

- Four-Stroke Engines:

- Z Series: ZL40/48, 16ZAV40S (Medium-speed engines).

- RF Series: RF44, RF56 (Often used for auxiliary power or generator sets).

- TAD Series: TAD36, TAD48 (For specific applications).

MAN (including pre and post-MAN B&W models):

- Two-Stroke Engines (KZ, KSZ, K, L, S, MC/MC-C, ME/ME-C): 40/54A, 52/90N, 57/80C, KZ57/80F, KSZ70/125, KSZ78/155, 90/160A, 52/55L, 58/64, 90/190C, L60/105E, 70/120E, 70/125C, L, KSZ78/155A, KSZ70/125B, L52/55A, 40/45 (A broad spectrum covering main propulsion and auxiliary engines).

B&W (Burmeister & Wain – prior to MAN B&W merger):

- MC/MCE Series: L35MC, L60MC, L80MC, L55GFCA, L80GFCA, L80GB, 74VT2BF, K62EF, K74EF, K84EF, K45GFC, K67GFK, K80GFK, K90GFS, 45HU, L70MC (Various generations of two-stroke diesel engines).

- MC-C/ME-C Series: L50MC, S60MC, S70MC, K80MC, S80MC, K90MC-C, L67GFCA, L90GB (Electronically controlled and conventional two-stroke engines).

- VT2BF/EF Series: 50VT2BF, 62VT2BF, K84EF (Older models still in service).

MITSUBISHI:

- UEC/UET Series: UEC37L/LA/LS, UEC45HA, UEC60L/LA/LS, UEC45L/LA/LS, UET45/75C, UEC52/125H, UEC52L/LA/LS, UET45/80D, UEC52/90D, UEC(T)52/105D, UEC45/115H, UEC37/88H, UEC37H (Mitsubishi’s proprietary two-stroke and some four-stroke engine series).

PIELSTICK:

- PA Series: PA6, PC3, PC2-2, IHI PC2-5, PC4, PC2-6, PC4-2L, PC4-570, PA5 (High-speed, compact four-stroke engines, commonly used for generator sets or auxiliary propulsion).

AKASAKA:

- UET/UEC/DM/AH Series: UET45/80D, UEC52/105D, DM51SS, UEC 60/150H, UEC 60H, A31, A34, A37, A41, AH27, AH28, AH30, AH36, AH38, AH40, DM30, DM36, DM38, DM46, DM47 (A prevalent engine brand, particularly in Japanese-built vessels).

DEUTZ:

- RBV/TBD/BVM Series: RBV8M358, RBV8M540, RBV16M640, TBD620L6, BVM350, BVM540, BF6M716 (Various four-stroke medium- and high-speed diesel engines for auxiliary and smaller main propulsion applications).

HANSHIN:

- EL/LH/LU/LUN/LUD/LUS Series: EL30, EL32, EL35, EL40, EL44, LH28RG, LH31G, LU28(A,R,G), LU32, LU35, LU38, LU46(A), LU50, LU54, LUN28, LUN30, LUD32, LUD35, LUS38 (Another significant engine brand commonly found in Japanese vessels).

NIIGATA:

- MG/M Series: MG40X(EX), M34X, 6M28BF, TM31X (Medium-speed diesel engines, typically used in small and medium-sized vessels).

MAK:

- M/MU/AK/AKM Series: M332, M453AK, MU551AK, MU552AK, M601, MU452AK, 451AK, 6M453AK, 9M453C, 6M601C, 8M601 (Medium-speed four-stroke engines, widely used in various marine applications).

WARTSILA:

- 20/22/26/32/38/46/GD/TKR Series: 22, 32, 31, 26, 20S, 28, 38, 46, 32GD, 46GD, 14, TKR22, HFR-V32, NOHAB (Wärtsilä’s broad portfolio of medium- and high-speed diesel engines for main propulsion, auxiliary, and generator sets).

DAIHATSU:

- PS/PKT/DS/DL/DK/PL Series: PS-18, PS-22, PS-20, PS-26, PS-30, PKT-14, PKT-16, PKTD-16, DS-18, DS-22, DS-26, DS-28, DS-32, DL-14, DL-16, DL-19, DL-20, DL-22, DL-24, DL-26, DK-20, PL-24 (Compact and reliable engines primarily used for auxiliary power and generator sets).

CUMMINS:

- BT/CT/NT/KTA/QSK/QSM Series: 4BT3.9, 6BT(A)5.9, 6CT8.3, NT(A)855, N14, KTA19, KTA38, KTA50, QSK19, QSM11 (Robust and durable engines for marine auxiliary power, generator sets, and some smaller main propulsion applications).

CATERPILLAR:

- 3000/3100/3300/3400/3500/3600 Series & C Series: 3054, 3056, 3066, 3106, 3126, 3306, 3406, 3408, 3412, 3508, 3512, 3516, 3606, 3608, 3612, 3616, 3618, C1.5, C2.2, C7, C9, C10, C12, C15, C16, C18, C30, C32 (Reliable and widely used engines across a vast range of main propulsion, auxiliary, and generator set applications).

SCANIA:

- DI Series: DI 09, DI 13, DI 16 (High-performance diesel engines designed for marine applications, typically used as auxiliary and smaller main propulsion engines).