A marine stern tube bearing is a vital component of a vessel’s propulsion system, situated within the stern tube.1 Its fundamental purpose is to support the weight of the propeller and the propeller shaft, allowing it to rotate smoothly while absorbing radial forces and vibrations. The performance and longevity of the entire shaft system depend heavily on the integrity of this bearing.

Here is a summary of the types, components, and common spare parts for a marine stern tube bearing.

Types and Materials

Stern tube bearings are classified primarily by their lubrication method, which also determines the material used.

- Oil-Lubricated Bearings:

- Principle: These bearings operate in a bath of lubricating oil, which is sealed from the seawater by stern shaft seals (as previously described).

- Materials: Typically made of white metal (Babbitt metal) or bronze.2 These materials offer excellent friction and wear resistance when properly lubricated.

- Advantages: Low friction, long life, and proven performance.

- Disadvantages: Risk of oil leaks, which can cause environmental pollution.

- Water-Lubricated Bearings:

- Principle: These bearings use seawater itself as the lubricant.3 The water is drawn from the outside, circulated through the stern tube, and then discharged overboard. A key benefit is the elimination of oil leakage.

- Materials: Modern water-lubricated bearings are made of high-tech composite materials or polymer blends (like Thordon’s SXL material) that are resistant to swelling and wear from sand and silt. Older systems used lignum vitae (a natural hardwood).

- Advantages: Environmentally friendly (no risk of oil pollution), and can handle abrasive particles better than white metal.

- Disadvantages: Can have a shorter lifespan than oil-lubricated bearings and are less suitable for high-speed applications.

- Principle: These bearings use seawater itself as the lubricant.3 The water is drawn from the outside, circulated through the stern tube, and then discharged overboard. A key benefit is the elimination of oil leakage.

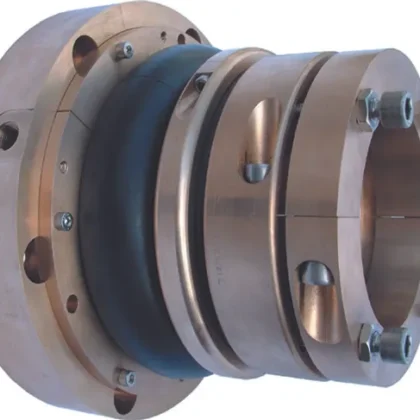

Core Components

A stern tube bearing system is more than just the bearing material; it includes the entire assembly within the stern tube.4

- Bearing Shell (or Bushing): The main component, typically a cylindrical shell with the bearing material lining the inner surface. It is often a split design for easier installation and removal.5

- Stern Tube: The robust casing that houses the bearing and the shaft seal. It is a watertight conduit that passes through the vessel’s hull.

- Shaft Liner: A corrosion-resistant sleeve fitted over the propeller shaft where it passes through the bearing.

- Lubrication System: For oil-lubricated bearings, this includes the oil header tank, pumps, and filters. For water-lubricated systems, it involves the seawater circulation system.

Common Spare Parts

Maintenance of stern tube bearings is essential to prevent catastrophic shaft damage and ensure smooth operation. Spare parts focus on the wearable components.

- Bearing Shells: The complete bearing shell or bushing. This is a crucial spare for major overhauls or unexpected wear.

- Bearing Inserts: For bearings with a split design, spare inserts or pads can be kept on board.

- Shaft Liners: The wearing sleeve that protects the shaft from direct contact with the bearing. A new liner is often required during a bearing change.

- Lubrication System Spares:

- Oil-Lubricated: Spares for the oil header tank, oil pumps, and oil filters.

- Water-Lubricated: Spares for the water circulation pump and any associated filters.

- Mounting Hardware: Spare bolts, nuts, and gaskets for securing the bearing assembly within the stern tube.

- Measuring Gauges: Specialized tools for measuring bearing wear and clearance are also a critical part of a vessel’s inventory.

Key Manufacturers

The market for stern tube bearings is dominated by specialized manufacturers:

- Thordon Bearings: A global leader in water-lubricated, polymer-based stern tube and rudder bearings.

- Wärtsilä: Offers a range of both oil-lubricated and environmentally friendly water-lubricated stern tube bearing systems.

- SKF Marine (Simplex-Compact): A well-known supplier of stern tube sealing and bearing systems, particularly oil-lubricated ones.

- IHC Lagersmit: Specializes in stern tube seals and bearings.

- Michell Bearings: Manufacturer of white metal and bronze-lined bearings for a wide range of marine applications.

Regular monitoring of bearing temperature and lubrication pressure, along with periodic inspections during dry-docking, are essential to ensure the bearing’s longevity and the integrity of the vessel’s propulsion system.

We offer an extensive range of marine engine brands and their associated spare parts, providing comprehensive solutions for both main propulsion and auxiliary power needs across diverse vessel types. Our supply capability covers various generations and models, ensuring support for a wide array of marine applications.

Featured Brands and Engine Series/Models:

SULZER:

- Two-Stroke Engines:

- RD/RND Series: RD68, RND76, RND76M, RND90, RND90M (Classic large-bore, low-speed engines, still in operation).

- RLA/RLB Series: RLA(B)56, RLA(B)66, RLA(B)76, RLB90 (Developed two-stroke designs).

- RTA/RT-Flex Series: RTA38, RTA48(T), RTA52, RTA58, RTA62, RTA72, RTA76, RTA84, RTA84M, RTA84C, RTA96 (Modern, fuel-efficient, electronically controlled two-stroke engines).

- Four-Stroke Engines:

- Z Series: ZL40/48, 16ZAV40S (Medium-speed engines).

- RF Series: RF44, RF56 (Often used for auxiliary power or generator sets).

- TAD Series: TAD36, TAD48 (For specific applications).

MAN (including pre and post-MAN B&W models):

- Two-Stroke Engines (KZ, KSZ, K, L, S, MC/MC-C, ME/ME-C): 40/54A, 52/90N, 57/80C, KZ57/80F, KSZ70/125, KSZ78/155, 90/160A, 52/55L, 58/64, 90/190C, L60/105E, 70/120E, 70/125C, L, KSZ78/155A, KSZ70/125B, L52/55A, 40/45 (A broad spectrum covering main propulsion and auxiliary engines).

B&W (Burmeister & Wain – prior to MAN B&W merger):

- MC/MCE Series: L35MC, L60MC, L80MC, L55GFCA, L80GFCA, L80GB, 74VT2BF, K62EF, K74EF, K84EF, K45GFC, K67GFK, K80GFK, K90GFS, 45HU, L70MC (Various generations of two-stroke diesel engines).

- MC-C/ME-C Series: L50MC, S60MC, S70MC, K80MC, S80MC, K90MC-C, L67GFCA, L90GB (Electronically controlled and conventional two-stroke engines).

- VT2BF/EF Series: 50VT2BF, 62VT2BF, K84EF (Older models still in service).

MITSUBISHI:

- UEC/UET Series: UEC37L/LA/LS, UEC45HA, UEC60L/LA/LS, UEC45L/LA/LS, UET45/75C, UEC52/125H, UEC52L/LA/LS, UET45/80D, UEC52/90D, UEC(T)52/105D, UEC45/115H, UEC37/88H, UEC37H (Mitsubishi’s proprietary two-stroke and some four-stroke engine series).

PIELSTICK:

- PA Series: PA6, PC3, PC2-2, IHI PC2-5, PC4, PC2-6, PC4-2L, PC4-570, PA5 (High-speed, compact four-stroke engines, commonly used for generator sets or auxiliary propulsion).

AKASAKA:

- UET/UEC/DM/AH Series: UET45/80D, UEC52/105D, DM51SS, UEC 60/150H, UEC 60H, A31, A34, A37, A41, AH27, AH28, AH30, AH36, AH38, AH40, DM30, DM36, DM38, DM46, DM47 (A prevalent engine brand, particularly in Japanese-built vessels).

DEUTZ:

- RBV/TBD/BVM Series: RBV8M358, RBV8M540, RBV16M640, TBD620L6, BVM350, BVM540, BF6M716 (Various four-stroke medium- and high-speed diesel engines for auxiliary and smaller main propulsion applications).

HANSHIN:

- EL/LH/LU/LUN/LUD/LUS Series: EL30, EL32, EL35, EL40, EL44, LH28RG, LH31G, LU28(A,R,G), LU32, LU35, LU38, LU46(A), LU50, LU54, LUN28, LUN30, LUD32, LUD35, LUS38 (Another significant engine brand commonly found in Japanese vessels).

NIIGATA:

- MG/M Series: MG40X(EX), M34X, 6M28BF, TM31X (Medium-speed diesel engines, typically used in small and medium-sized vessels).

MAK:

- M/MU/AK/AKM Series: M332, M453AK, MU551AK, MU552AK, M601, MU452AK, 451AK, 6M453AK, 9M453C, 6M601C, 8M601 (Medium-speed four-stroke engines, widely used in various marine applications).

WARTSILA:

- 20/22/26/32/38/46/GD/TKR Series: 22, 32, 31, 26, 20S, 28, 38, 46, 32GD, 46GD, 14, TKR22, HFR-V32, NOHAB (Wärtsilä’s broad portfolio of medium- and high-speed diesel engines for main propulsion, auxiliary, and generator sets).

DAIHATSU:

- PS/PKT/DS/DL/DK/PL Series: PS-18, PS-22, PS-20, PS-26, PS-30, PKT-14, PKT-16, PKTD-16, DS-18, DS-22, DS-26, DS-28, DS-32, DL-14, DL-16, DL-19, DL-20, DL-22, DL-24, DL-26, DK-20, PL-24 (Compact and reliable engines primarily used for auxiliary power and generator sets).

CUMMINS:

- BT/CT/NT/KTA/QSK/QSM Series: 4BT3.9, 6BT(A)5.9, 6CT8.3, NT(A)855, N14, KTA19, KTA38, KTA50, QSK19, QSM11 (Robust and durable engines for marine auxiliary power, generator sets, and some smaller main propulsion applications).

CATERPILLAR:

- 3000/3100/3300/3400/3500/3600 Series & C Series: 3054, 3056, 3066, 3106, 3126, 3306, 3406, 3408, 3412, 3508, 3512, 3516, 3606, 3608, 3612, 3616, 3618, C1.5, C2.2, C7, C9, C10, C12, C15, C16, C18, C30, C32 (Reliable and widely used engines across a vast range of main propulsion, auxiliary, and generator set applications).

SCANIA:

- DI Series: DI 09, DI 13, DI 16 (High-performance diesel engines designed for marine applications, typically used as auxiliary and smaller main propulsion engines).