A marine shaft grounding device, also known as a shaft earthing system, is a vital electrical component on a vessel’s propeller shaft.1 Its primary purpose is to provide a low-resistance path for stray electrical currents to flow from the rotating shaft to the ship’s hull, or ground.2 This prevents these currents from passing through sensitive components like bearings, which can cause severe damage.3

The Problem It Solves: Bearing Corrosion

A rotating propeller shaft is electrically insulated from the ship’s hull by the lubricating oil film in the stern tube and intermediate bearings.4 This insulation can lead to a build-up of electrical potential between the shaft and the hull.5 This potential difference can be caused by:

- Galvanic Corrosion: Different metals in seawater (e.g., a bronze propeller and a steel shaft) create a galvanic cell.6

- Stray Currents: Small electrical currents leaking from a vessel’s electrical systems.7

- VFD (Variable Frequency Drive) Harmonics: Modern propulsion systems using VFDs can induce currents onto the shaft.8

If this potential is not grounded, the electrical current will discharge by arcing or sparking across the thin oil film in the bearings. This process, known as spark erosion or pitting, causes microscopic damage to the bearing surfaces.9 Over time, this leads to premature bearing failure, increased vibration, and costly repairs.10

Components of a Grounding Device

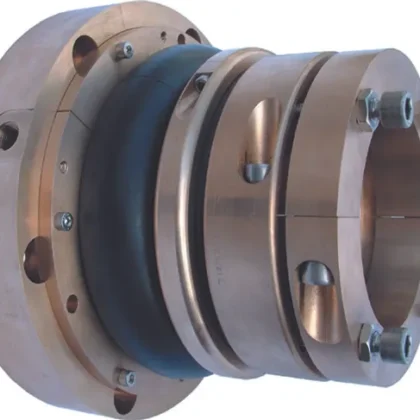

A typical marine shaft grounding device consists of three main parts:

- Slip Ring: A conductive ring (often copper with a silver inlay) is clamped or fitted securely onto the propeller shaft.11 The silver track provides a highly conductive, low-resistance surface for the brushes to run on.12

- Brush Holder: A non-conductive holder is mounted to the engine bed or hull structure, positioning the brushes to maintain constant contact with the slip ring.13

- Brushes: Made from a highly conductive material, typically a composite of silver and graphite, these brushes are spring-loaded to ensure continuous contact with the slip ring.14 A grounding cable connects the brush holder to the hull.

The system works by creating a direct, low-resistance electrical path that allows any potential to dissipate safely to the hull, bypassing the bearings entirely.15

Maintenance and Common Spares

Regular maintenance is critical to ensure the grounding device remains effective.

- Monitoring: The potential difference between the shaft and the hull should be monitored.16 A reading above a manufacturer-specified threshold (often around 50 mV) indicates a problem.17

- Inspection: Brushes and the slip ring should be inspected periodically for wear, dirt, oil, or grease contamination.18 A contaminated slip ring can increase resistance, rendering the system useless.

- Brush Replacement: Brushes are a wearable component and must be replaced when they are worn down to a minimum level.

Common Spares include:

- Spare Brushes: The most frequently required spare part.

- Spare Springs: To ensure proper pressure is maintained on the brushes.19

- Spare Slip Ring: In case the slip ring becomes damaged or excessively worn.

- Cleaning Materials: Specialized cleaning tools and solvents for the slip ring.20

Key Manufacturers

The market for these devices includes specialist manufacturers of cathodic protection and electrical systems.

- Wärtsilä: A major manufacturer of propulsion systems that also supplies shaft grounding devices.

- SKF Marine: A leader in bearings and condition monitoring that provides comprehensive shaft grounding solutions.

- Althen Controls: A manufacturer of sensors and monitoring systems, including propeller shaft earthing sets.21

- MME Group: A company specializing in cathodic protection and shaft grounding systems.22

A properly installed and maintained marine shaft grounding device is an inexpensive but essential line of defense that protects a vessel’s most expensive components from electrical damage.23

We offer an extensive range of marine engine brands and their associated spare parts, providing comprehensive solutions for both main propulsion and auxiliary power needs across diverse vessel types. Our supply capability covers various generations and models, ensuring support for a wide array of marine applications.

Featured Brands and Engine Series/Models:

SULZER:

- Two-Stroke Engines:

- RD/RND Series: RD68, RND76, RND76M, RND90, RND90M (Classic large-bore, low-speed engines, still in operation).

- RLA/RLB Series: RLA(B)56, RLA(B)66, RLA(B)76, RLB90 (Developed two-stroke designs).

- RTA/RT-Flex Series: RTA38, RTA48(T), RTA52, RTA58, RTA62, RTA72, RTA76, RTA84, RTA84M, RTA84C, RTA96 (Modern, fuel-efficient, electronically controlled two-stroke engines).

- Four-Stroke Engines:

- Z Series: ZL40/48, 16ZAV40S (Medium-speed engines).

- RF Series: RF44, RF56 (Often used for auxiliary power or generator sets).

- TAD Series: TAD36, TAD48 (For specific applications).

MAN (including pre and post-MAN B&W models):

- Two-Stroke Engines (KZ, KSZ, K, L, S, MC/MC-C, ME/ME-C): 40/54A, 52/90N, 57/80C, KZ57/80F, KSZ70/125, KSZ78/155, 90/160A, 52/55L, 58/64, 90/190C, L60/105E, 70/120E, 70/125C, L, KSZ78/155A, KSZ70/125B, L52/55A, 40/45 (A broad spectrum covering main propulsion and auxiliary engines).

B&W (Burmeister & Wain – prior to MAN B&W merger):

- MC/MCE Series: L35MC, L60MC, L80MC, L55GFCA, L80GFCA, L80GB, 74VT2BF, K62EF, K74EF, K84EF, K45GFC, K67GFK, K80GFK, K90GFS, 45HU, L70MC (Various generations of two-stroke diesel engines).

- MC-C/ME-C Series: L50MC, S60MC, S70MC, K80MC, S80MC, K90MC-C, L67GFCA, L90GB (Electronically controlled and conventional two-stroke engines).

- VT2BF/EF Series: 50VT2BF, 62VT2BF, K84EF (Older models still in service).

MITSUBISHI:

- UEC/UET Series: UEC37L/LA/LS, UEC45HA, UEC60L/LA/LS, UEC45L/LA/LS, UET45/75C, UEC52/125H, UEC52L/LA/LS, UET45/80D, UEC52/90D, UEC(T)52/105D, UEC45/115H, UEC37/88H, UEC37H (Mitsubishi’s proprietary two-stroke and some four-stroke engine series).

PIELSTICK:

- PA Series: PA6, PC3, PC2-2, IHI PC2-5, PC4, PC2-6, PC4-2L, PC4-570, PA5 (High-speed, compact four-stroke engines, commonly used for generator sets or auxiliary propulsion).

AKASAKA:

- UET/UEC/DM/AH Series: UET45/80D, UEC52/105D, DM51SS, UEC 60/150H, UEC 60H, A31, A34, A37, A41, AH27, AH28, AH30, AH36, AH38, AH40, DM30, DM36, DM38, DM46, DM47 (A prevalent engine brand, particularly in Japanese-built vessels).

DEUTZ:

- RBV/TBD/BVM Series: RBV8M358, RBV8M540, RBV16M640, TBD620L6, BVM350, BVM540, BF6M716 (Various four-stroke medium- and high-speed diesel engines for auxiliary and smaller main propulsion applications).

HANSHIN:

- EL/LH/LU/LUN/LUD/LUS Series: EL30, EL32, EL35, EL40, EL44, LH28RG, LH31G, LU28(A,R,G), LU32, LU35, LU38, LU46(A), LU50, LU54, LUN28, LUN30, LUD32, LUD35, LUS38 (Another significant engine brand commonly found in Japanese vessels).

NIIGATA:

- MG/M Series: MG40X(EX), M34X, 6M28BF, TM31X (Medium-speed diesel engines, typically used in small and medium-sized vessels).

MAK:

- M/MU/AK/AKM Series: M332, M453AK, MU551AK, MU552AK, M601, MU452AK, 451AK, 6M453AK, 9M453C, 6M601C, 8M601 (Medium-speed four-stroke engines, widely used in various marine applications).

WARTSILA:

- 20/22/26/32/38/46/GD/TKR Series: 22, 32, 31, 26, 20S, 28, 38, 46, 32GD, 46GD, 14, TKR22, HFR-V32, NOHAB (Wärtsilä’s broad portfolio of medium- and high-speed diesel engines for main propulsion, auxiliary, and generator sets).

DAIHATSU:

- PS/PKT/DS/DL/DK/PL Series: PS-18, PS-22, PS-20, PS-26, PS-30, PKT-14, PKT-16, PKTD-16, DS-18, DS-22, DS-26, DS-28, DS-32, DL-14, DL-16, DL-19, DL-20, DL-22, DL-24, DL-26, DK-20, PL-24 (Compact and reliable engines primarily used for auxiliary power and generator sets).

CUMMINS:

- BT/CT/NT/KTA/QSK/QSM Series: 4BT3.9, 6BT(A)5.9, 6CT8.3, NT(A)855, N14, KTA19, KTA38, KTA50, QSK19, QSM11 (Robust and durable engines for marine auxiliary power, generator sets, and some smaller main propulsion applications).

CATERPILLAR:

- 3000/3100/3300/3400/3500/3600 Series & C Series: 3054, 3056, 3066, 3106, 3126, 3306, 3406, 3408, 3412, 3508, 3512, 3516, 3606, 3608, 3612, 3616, 3618, C1.5, C2.2, C7, C9, C10, C12, C15, C16, C18, C30, C32 (Reliable and widely used engines across a vast range of main propulsion, auxiliary, and generator set applications).

SCANIA:

- DI Series: DI 09, DI 13, DI 16 (High-performance diesel engines designed for marine applications, typically used as auxiliary and smaller main propulsion engines).