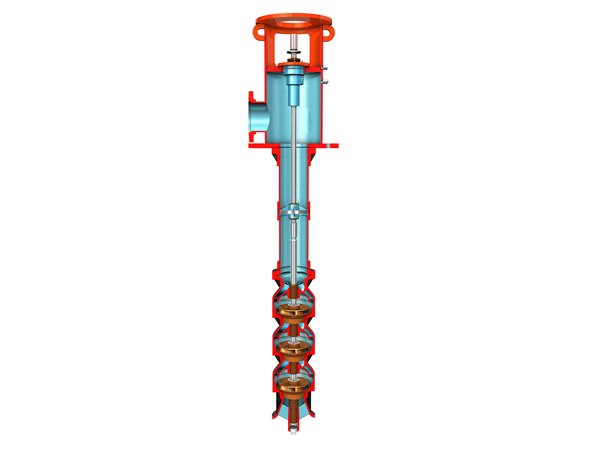

A vertical deep-well oil pump is a specialized type of centrifugal pump primarily used on tankers and other vessels carrying liquid cargo. Its unique design is engineered to overcome the challenges of transferring fluids from deep cargo tanks, a task that would be difficult for a conventional centrifugal pump. It is a vertical, multi-stage pump where the pumping element (impeller) is located at the bottom of the tank, and the motor is positioned on the deck.

Working Principle

The deep-well pump’s core principle is to eliminate the need for a long suction line and priming system.

- Submerged Impeller: The pump casing and impeller are fully submerged in the liquid cargo at the bottom of the tank. The static head pressure of the cargo naturally keeps the pump “primed” at all times.

- Long Vertical Shaft: An electric or hydraulic motor, located on the main deck, drives a long vertical shaft that extends down into the tank. This shaft connects directly to the impeller(s) at the bottom.

- Discharge: The pump draws in liquid from the bottom of the tank and discharges it upwards through a discharge pipe that runs parallel to the pump shaft, delivering the cargo to the deck manifold.

This design ensures efficient and complete cargo discharge, as the pump can continue to operate even when the tank’s liquid level is very low.

Main Components and Materials

A deep-well pump is a complex assembly that extends from the weather deck to the bottom of the cargo tank.

- Motor: The motor (electric or hydraulic) is mounted on the deck stool. It is a critical component and must be rated for hazardous atmospheres.

- Pump Head Assembly: The top part on deck that houses the motor, the shaft seal (to prevent cargo vapor leakage), and the discharge connection.

- Drive Shaft: A long, vertical shaft (or a series of shorter sections connected by couplings) that transmits power from the motor to the impeller.

- Shaft Bearings: Guide bearings are placed at intervals along the shaft to prevent it from whipping or vibrating inside the discharge pipe. These are often lubricated by the cargo itself.

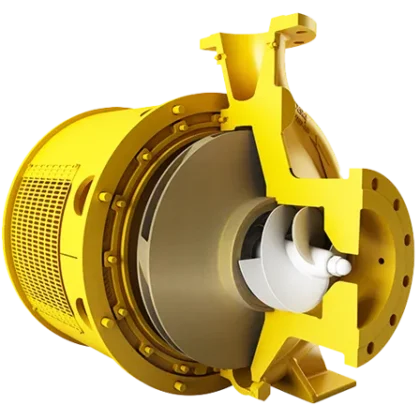

- Pump Casing: The lower section of the pump, located in the tank, which houses the impeller(s).

- Impeller(s): The rotating element(s) that move the liquid cargo. The pump may have a single-stage or multi-stage design (multiple impellers) to achieve the necessary head and flow rate.

Materials: Given that these pumps handle a variety of corrosive and volatile cargoes, the materials are carefully selected.

- Shaft, Impeller, and Casing: Typically made of high-quality stainless steel or bronze for corrosion resistance.

- Seals and Bearings: Selected to be compatible with the specific cargo being handled.

Marine Applications and Maintenance

Deep-well pumps are indispensable for the safe and efficient handling of liquid cargoes.

- Primary Application: Cargo pumps on tankers, chemical carriers, and gas carriers. They are used for both loading and discharging cargo.

- Stripping Operations: Their design allows them to effectively “strip” or empty the tanks of the last remaining liquid, minimizing cargo residue (ROB – Remaining On Board).

Maintenance:

- Shaft and Bearings: Regular inspection of the shaft bearings is critical to prevent vibration.

- Impeller: The impeller and casing should be inspected for corrosion or damage from solid particles in the cargo.

- Deck Seals: Seals on the pump head must be monitored to prevent leakage of cargo vapors.

- Motor: The electric motor on deck requires standard electrical maintenance.

Common Spares

A vessel’s spares inventory for deep-well pumps is focused on components that are subject to wear and corrosion.

- Impeller(s): Spare impellers are crucial in case of damage from corrosion or cavitation.

- Shaft Bearings: A set of spare bearings for the pump shaft.

- Mechanical Seal Kit: Spares for the deck seal to prevent leakage.

- Shaft Sections: A spare section of the pump shaft in case of failure.

- O-rings and Gaskets: For assembly and sealing.

Vertical deep-well oil pumps are a cornerstone of a tanker’s cargo handling system, providing the reliability and performance required for safe and profitable operations.

We offer an extensive range of marine engine brands and their associated spare parts, providing comprehensive solutions for both main propulsion and auxiliary power needs across diverse vessel types. Our supply capability covers various generations and models, ensuring support for a wide array of marine applications.

Featured Brands and Engine Series/Models:

SULZER:

- Two-Stroke Engines:

- RD/RND Series: RD68, RND76, RND76M, RND90, RND90M (Classic large-bore, low-speed engines, still in operation).

- RLA/RLB Series: RLA(B)56, RLA(B)66, RLA(B)76, RLB90 (Developed two-stroke designs).

- RTA/RT-Flex Series: RTA38, RTA48(T), RTA52, RTA58, RTA62, RTA72, RTA76, RTA84, RTA84M, RTA84C, RTA96 (Modern, fuel-efficient, electronically controlled two-stroke engines).

- Four-Stroke Engines:

- Z Series: ZL40/48, 16ZAV40S (Medium-speed engines).

- RF Series: RF44, RF56 (Often used for auxiliary power or generator sets).

- TAD Series: TAD36, TAD48 (For specific applications).

MAN (including pre and post-MAN B&W models):

- Two-Stroke Engines (KZ, KSZ, K, L, S, MC/MC-C, ME/ME-C): 40/54A, 52/90N, 57/80C, KZ57/80F, KSZ70/125, KSZ78/155, 90/160A, 52/55L, 58/64, 90/190C, L60/105E, 70/120E, 70/125C, L, KSZ78/155A, KSZ70/125B, L52/55A, 40/45 (A broad spectrum covering main propulsion and auxiliary engines).

B&W (Burmeister & Wain – prior to MAN B&W merger):

- MC/MCE Series: L35MC, L60MC, L80MC, L55GFCA, L80GFCA, L80GB, 74VT2BF, K62EF, K74EF, K84EF, K45GFC, K67GFK, K80GFK, K90GFS, 45HU, L70MC (Various generations of two-stroke diesel engines).

- MC-C/ME-C Series: L50MC, S60MC, S70MC, K80MC, S80MC, K90MC-C, L67GFCA, L90GB (Electronically controlled and conventional two-stroke engines).

- VT2BF/EF Series: 50VT2BF, 62VT2BF, K84EF (Older models still in service).

MITSUBISHI:

- UEC/UET Series: UEC37L/LA/LS, UEC45HA, UEC60L/LA/LS, UEC45L/LA/LS, UET45/75C, UEC52/125H, UEC52L/LA/LS, UET45/80D, UEC52/90D, UEC(T)52/105D, UEC45/115H, UEC37/88H, UEC37H (Mitsubishi’s proprietary two-stroke and some four-stroke engine series).

PIELSTICK:

- PA Series: PA6, PC3, PC2-2, IHI PC2-5, PC4, PC2-6, PC4-2L, PC4-570, PA5 (High-speed, compact four-stroke engines, commonly used for generator sets or auxiliary propulsion).

AKASAKA:

- UET/UEC/DM/AH Series: UET45/80D, UEC52/105D, DM51SS, UEC 60/150H, UEC 60H, A31, A34, A37, A41, AH27, AH28, AH30, AH36, AH38, AH40, DM30, DM36, DM38, DM46, DM47 (A prevalent engine brand, particularly in Japanese-built vessels).

DEUTZ:

- RBV/TBD/BVM Series: RBV8M358, RBV8M540, RBV16M640, TBD620L6, BVM350, BVM540, BF6M716 (Various four-stroke medium- and high-speed diesel engines for auxiliary and smaller main propulsion applications).

HANSHIN:

- EL/LH/LU/LUN/LUD/LUS Series: EL30, EL32, EL35, EL40, EL44, LH28RG, LH31G, LU28(A,R,G), LU32, LU35, LU38, LU46(A), LU50, LU54, LUN28, LUN30, LUD32, LUD35, LUS38 (Another significant engine brand commonly found in Japanese vessels).

NIIGATA:

- MG/M Series: MG40X(EX), M34X, 6M28BF, TM31X (Medium-speed diesel engines, typically used in small and medium-sized vessels).

MAK:

- M/MU/AK/AKM Series: M332, M453AK, MU551AK, MU552AK, M601, MU452AK, 451AK, 6M453AK, 9M453C, 6M601C, 8M601 (Medium-speed four-stroke engines, widely used in various marine applications).

WARTSILA:

- 20/22/26/32/38/46/GD/TKR Series: 22, 32, 31, 26, 20S, 28, 38, 46, 32GD, 46GD, 14, TKR22, HFR-V32, NOHAB (Wärtsilä’s broad portfolio of medium- and high-speed diesel engines for main propulsion, auxiliary, and generator sets).

DAIHATSU:

- PS/PKT/DS/DL/DK/PL Series: PS-18, PS-22, PS-20, PS-26, PS-30, PKT-14, PKT-16, PKTD-16, DS-18, DS-22, DS-26, DS-28, DS-32, DL-14, DL-16, DL-19, DL-20, DL-22, DL-24, DL-26, DK-20, PL-24 (Compact and reliable engines primarily used for auxiliary power and generator sets).

CUMMINS:

- BT/CT/NT/KTA/QSK/QSM Series: 4BT3.9, 6BT(A)5.9, 6CT8.3, NT(A)855, N14, KTA19, KTA38, KTA50, QSK19, QSM11 (Robust and durable engines for marine auxiliary power, generator sets, and some smaller main propulsion applications).

CATERPILLAR:

- 3000/3100/3300/3400/3500/3600 Series & C Series: 3054, 3056, 3066, 3106, 3126, 3306, 3406, 3408, 3412, 3508, 3512, 3516, 3606, 3608, 3612, 3616, 3618, C1.5, C2.2, C7, C9, C10, C12, C15, C16, C18, C30, C32 (Reliable and widely used engines across a vast range of main propulsion, auxiliary, and generator set applications).

SCANIA:

- DI Series: DI 09, DI 13, DI 16 (High-performance diesel engines designed for marine applications, typically used as auxiliary and smaller main propulsion engines).