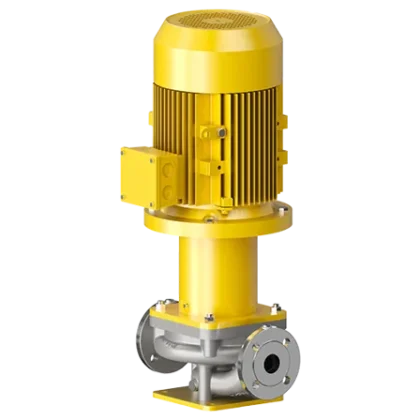

Proven KRAL pump quality suitable even for aggressive and contaminated media.

In the new Z series, KRAL applies its expertise in pump design and technology to two screw pumps. As a result, the KRAL Z series is capable of delivering aggressive, low- or non-lubricating, and contaminated media with the reliability and quality that KRAL products are valued for by customers worldwide.

Operation, materials, components.

- Delivery rate: 330 to 17,660 l/min or 20 to 1,060 m³/h.

- Max. differential pressure: 25 bar.

- Temperature range in the pumped media: -40 °C to +300 °C.

- Housing: Ductile iron or welded steel.

- Screws: Solid or engineered.

- Approvals: ABS, BV, DNV-GL, LRS, RINA, others on request.

- ATEX: Device Group II, Device Category 2.

- Heating: Electrical, media or steam.

- API: Manufacturing according to API 676 possible.

How it works.

The KRAL Z series pumps are positive displacement pumps that draw the liquid through the suction connection and continually feed it in two partial streams to the two screws. As a result, the pump is pressure-equalized axially. The pressure builds up linearly along the length of the screw. The housing design ensures that the gap between the screws and the housing remains sealed. This ensures that the pump can be primed very effectively, even when the suction line is empty.

Customized solution.

The KRAL Z series can be implemented as a customized solution for any required application. For example, depending on the application, the screws can be designed solid or engineered. This results in substantial benefits for important aspects such as fatigue strength, media resistance, maintenance costs, and costs over the life-cycle of the pump.