KRAL magnetic coupling screw pumps pay for themselves quickly: they are maintenance-free, hermetically sealed (no product leakage, no crystallization of the pumped media) and temperature-resistant up to 300 °C. Frequent replacement of mechanical seals is no longer necessary, a single installation of a magnetic drive screw pump is sufficient. This saves costs.

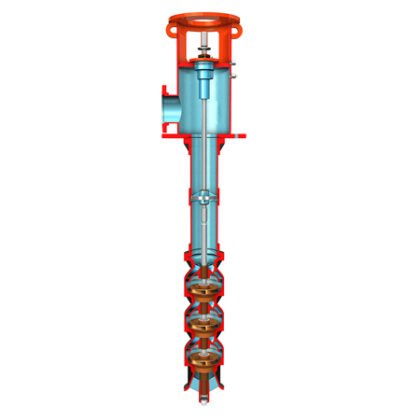

Operation, materials, components.

- Delivery rate: 5 to 3,500 l/min.

- Max. differential pressure: 100 bar.

- Temperature range: -20 °C to 300 °C.

- Housing: Nodular cast iron EN-GJS-400, steel and aluminium.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

Leakage-free and clean.

Critical fluids containing substances endangering the health or the environment should not leak to the atmosphere. In contrast to conventional shaft seals, KRAL screw pumps with magnetic coupling are hermetically sealed by the integrated containment can. People and the environment are not endangered.

Can be used up to 300 °C.

Thermal distortion and the temperature limits of elastomeric sealing elements restrict the use of screw pumps in high temperature applications. If temperatures up to 300 °C are handled, KRAL screw pumps with magnetic coupling are the right choice.

Reduced lifecycle costs.

Spare parts and maintenance costs for mechanical seals increase the life cycle costs. Mechanical seals in KRAL screw pumps have a high technological standard. Even during proper operation, however, they are still a wearing part. KRAL screw pumps with magnetic coupling are maintenance-free and pay for themselves after just three years.