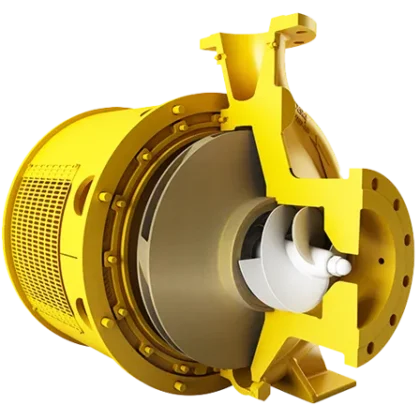

Operation, materials, components.

- Delivery rate: 5 to 280 l/min.

- Max. differential pressure: 40 bar.

- Temperature range: -20 °C to 180 °C.

- Housing: Nodular cast iron EN-GJS-400.

- Triple screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

- Seal type: Mechanical seal standard or hard material.

- Available with magnetic coupling.

In the case of a ship, the failure of the fuel screw pump in the booster module means that the engine comes to a standstill. If the flame goes out in a burner, a production process will be interrupted or a heating system will fail. Such applications require security. For maintenance, the primary screw pump can be switched to the standby screw pump, without interruption.

Cost reduction through many functions in compact space.

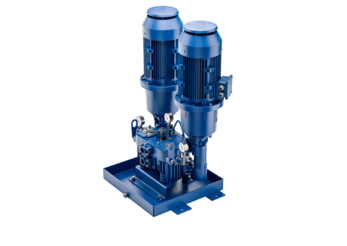

If a second screw pump is necessary, it soon becomes clear that the cost of design, pipework and control is considerable. The space requirement for a structure involving individual components is also very large. A significantly more economical solution is represented by the completely newly developed DKC and DLC dual stations by KRAL. Two screw pumps of the K series up to 16 bar or L series up to 63 bar are fitted to one block. The block integrates all functions within minimum space, and is available with many further options. And the flow rate can be doubled.

Alternate operation between two liquids.

For alternate operation between light and heavy oil operation, for example, the operator does not have to carry out any complex pipework when using KRAL pump stations. As an option, a liquid changeover switch can be fitted. In this way, KRAL dual stations are connected to two pipeline systems with different liquids. Switching between the liquids is manual, electrical or pneumatic. For remote monitoring of the lever position, limit switches are available.