MacGregor electric-driven deck machinery refers to a range of shipboard equipment, such as cranes, winches, and hatch covers, that utilize electric motors and advanced control systems instead of traditional hydraulic power.1 As a leading manufacturer of cargo handling and deck equipment, MacGregor has been at the forefront of the industry’s shift towards more energy-efficient, environmentally friendly, and digitally integrated solutions.

Working Principle

Electric-driven deck machinery operates by converting electrical energy directly into mechanical motion.2 A Variable Frequency Drive (VFD) is a core component of this system.3

- Electric Motor: An electric motor, typically an AC motor, is the power source that drives the gears and drums of the machinery.4

- Variable Frequency Drive (VFD): The VFD controls the speed and torque of the motor by adjusting the frequency and voltage of the electrical power.5 This provides precise, stepless speed control, which is crucial for sensitive operations like hoisting and mooring.6

- Mechanical Drive: The motor drives a compact gearbox, which transmits power to the winch drum, crane hoist, or hatch cover rack.

This contrasts with hydraulic systems, which use a central hydraulic power unit (HPU) to pressurize fluid, which is then sent through a complex network of hoses and valves to a hydraulic motor at the point of action.

Key Types of MacGregor Electric-Driven Machinery

MacGregor offers a full portfolio of electric-driven equipment for various vessel types:7

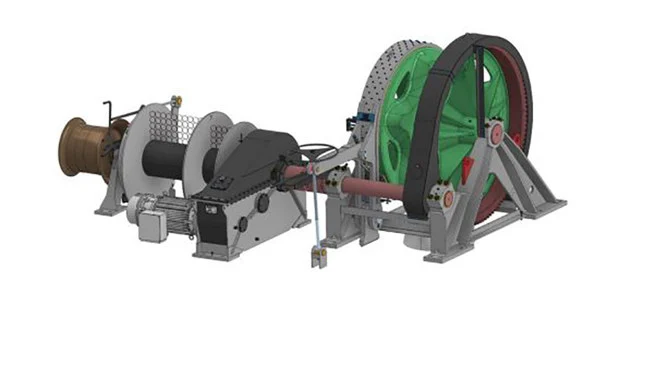

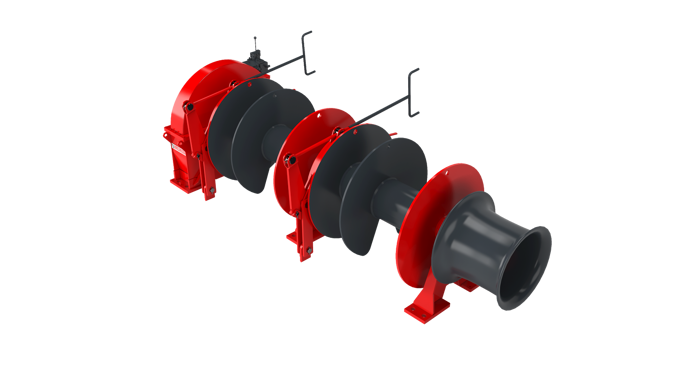

- Electric-Driven Winches: This includes anchor windlasses, mooring winches, and combined anchor-mooring winches. Their VFD-controlled drives allow for precise tensioning and faster, more reliable mooring operations.

- Electric Cranes: MacGregor has a long history with electric cranes, which are used for cargo handling, lifting hatch covers, and other operations.8 The electric drives can cut power consumption by up to 50% compared to traditional hydraulic designs.9

- Electric Hatch Covers: Systems like MacGregor’s MacRack use a combined electric rack-and-pinion drive and lifter system for efficient and reliable opening and closing of hatch covers, eliminating the need for hydraulic pipework.10

Advantages of Electric-Driven Systems

The shift to electric drives offers significant operational and environmental benefits:

- Energy Efficiency: Electric systems consume less power, reducing fuel consumption and operational expenditure (OpEx).11

- Environmental Protection: The absence of hydraulic oil eliminates the risk of oil spills, making the equipment safer for the crew and the marine environment.12

- Reduced Maintenance: With fewer components and no hydraulic hoses, filters, or pumps, electric systems have lower maintenance requirements and fewer consumables.13

- Improved Control and Performance: VFDs allow for superior speed control, faster operation, and precise positioning, which can reduce port turnaround times.14

- Compact Design: Electric systems are generally more compact and easier to install, as they do not require extensive hydraulic piping.15

- Noise Reduction: Electric motors operate more quietly than hydraulic power units.16

Maintenance and Common Spares

Maintenance for electric-driven machinery focuses on the electrical and mechanical components.

- Routine Maintenance: Inspections of the motor, gearbox, and brake systems are critical. The VFD’s cooling system (fans and filters) must be kept clean. Regular checks of electrical connections, cables, and sensors are also essential.

- Common Issues: Potential problems include electrical faults, component failure in the VFD, motor winding issues, and wear on mechanical components like gears and brakes.

Common Spares include:

- Electrical Components: Fuses, contactors, relays, and circuit boards.

- VFD Spares: Power modules, control cards, and cooling fans.

- Motor Spares: Bearings and seals.

- Mechanical Parts: Brake pads and discs, gaskets, and seals for the gearbox.

- Sensors: Spare limit switches and load sensors.

MacGregor’s electric-driven deck machinery represents a modern, sustainable, and high-performance alternative to hydraulic systems, reflecting the maritime industry’s increasing focus on efficiency and decarbonization.