You can purchase Valsteam ADCA special equipment and components at competitive prices from our company. As a long-term partner with Valsteam ADCA, we have the advantage of supplying original units and parts with minimal markup for worldwide delivery. We can also assist with the selection, design, and installation of these highly engineered solutions. A personal manager will explain the step-by-step process for purchasing this specialized equipment.

Valsteam ADCA’s special equipment represents their ability to provide tailor-made solutions for complex industrial fluid control challenges. These are not standard, off-the-shelf products but rather highly engineered systems or components designed for specific, demanding applications, particularly in the pharmaceutical, food & beverage, and chemical industries. This category highlights their deep engineering expertise and commitment to solving intricate fluid process problems.

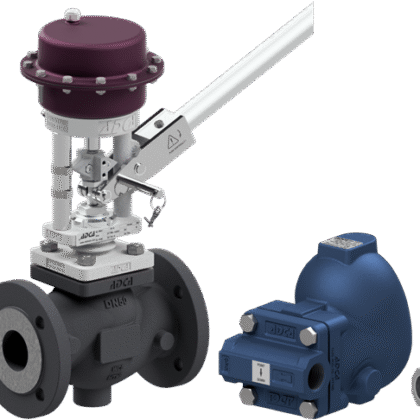

Valsteam ADCA Special Equipment & Applications

Valsteam ADCA offers a range of specialized equipment that addresses unique requirements in various industries. Some of the key product types include:

- ADCAMat Pressure-Operated Pumps: These are used to transfer steam condensate, oils, and other non-hazardous liquids to a higher elevation or pressure. They can be operated by steam or compressed air, making them ideal for locations without electricity. An automatic pump trap combines a float steam trap and a pressure-operated pump into a single unit, which is particularly useful where “stall” conditions may occur.

- Clean Steam Equipment (ADCAPure Series): The ADCAPure line is specifically designed for industries with high-purity demands. This includes sanitary steam traps (like the all-stainless steel TSS6 series) and sanitary sampling valves (HSV series) for use in reactors, sterilizers, and clean steam distribution lines. These products feature hygienic designs, are self-draining, and are made from low-ferrite stainless steel.

- Sample Coolers: These devices are used to cool down high-temperature liquid or steam samples, such as boiler water, for safe and accurate analysis. The SC32 sample cooler, for instance, prevents dangerous “flash-off” and ensures an accurate sample is obtained.

- Integrated Packages: Valsteam ADCA can design and supply “plug-and-play” packages, such as the ADCAMat PPT-K packaged pump trap unit. These are pre-mounted, piped, and ready for connection, saving significant on-site installation time and costs while ensuring optimal performance.

Key Features

Valsteam ADCA’s special equipment is valued for the following characteristics:

- Custom Engineering: The equipment can be configured and, in some cases, custom-built to meet specific process requirements, pressures, and temperatures.

- High-Quality Materials: Products are typically manufactured from stainless steel and other high-grade materials to ensure hygiene, corrosion resistance, and durability.

- Process Efficiency: Solutions like condensate recovery pumps and steam separators maximize energy recovery and ensure the quality of steam, improving overall system efficiency.

- Safety and Compliance: The equipment is designed to meet stringent industry regulations, especially in the pharmaceutical and food sectors, ensuring both process integrity and operator safety.

To receive a commercial offer for the supply of Valsteam ADCA special equipment, please contact our specialists. To create a request, you’ll need to provide comprehensive information about your application, including the fluid, required pressure, temperature, and flow rate, to ensure the solution is precisely tailored to your needs.