You can purchase genuine Sumitomo gearboxes and servo transmissions at competitive prices from our company. As a long-term partner with Sumitomo Drive Technologies, we have the advantage of supplying original units and parts with minimal markup for worldwide delivery. We can also assist with the selection, sizing, and maintenance of these critical devices. A personal manager will explain the step-by-step process for purchasing a Sumitomo component.

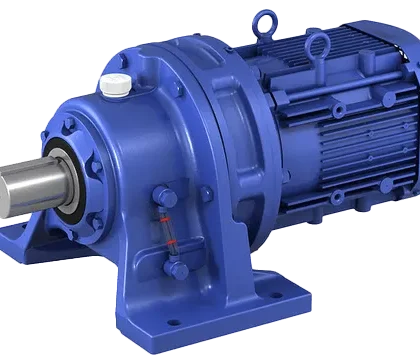

Sumitomo Drive Technologies is a global leader in the power transmission industry, providing a wide range of gearboxes and specialized servo transmissions. A gearbox (or gear reducer) is a mechanical device that reduces a motor’s speed and increases its torque for industrial applications. A servo transmission, on the other hand, is a highly precise gearbox specifically designed to work with servo motors in applications that require minimal backlash and maximum accuracy.

Sumitomo Gearbox & Servo Transmission Categories

Sumitomo’s portfolio is divided into two main categories to serve both general industrial and high-precision motion control needs:

- Industrial Gearboxes (General Purpose): These gearboxes are built for durability and high-torque applications. The most famous is the Cyclo® Drive, which uses a unique epicycloidal design to provide unmatched shock load capacity and reliability. Other categories include:

- Helical Gearboxes: Such as the Helical Shaft Mount (HSM) and Bevel Buddybox® (BBB) series, known for high efficiency and quiet operation.

- Planetary Gearboxes: Like the Paramax® series, which offers a compact design with high torque density, ideal for heavy-duty applications.

- Worm Gearboxes: The Hedcon® series uses double-enveloping worm gearing for higher torque and efficiency than conventional worm drives.

- High-Precision Servo Transmissions: These are specifically engineered to provide low backlash and high stiffness for precise motion control applications, such as robotics and machine tools. Key series include:

- Fine Cyclo®: This series uses a unique cycloidal mechanism to achieve near-zero backlash (<1 arcmin), making it ideal for applications that demand extreme precision, repeatability, and resistance to shock loads. The design features a large contact area, which enhances durability and torque capacity.

- E-Cyclo®: A more compact and cost-effective version of the Fine Cyclo®, the E-Cyclo® series integrates a strain wave gearing mechanism with the cycloidal design. It offers high rigidity and low backlash in a smaller, lighter package.

- IB Series Planetary Servo Gearboxes: These precision planetary gearboxes offer low backlash and are suitable for a wide range of servo motor applications.

Key Features

Sumitomo’s gearboxes and servo transmissions are highly valued for the following characteristics:

- Unmatched Durability: The unique cycloidal design of the Cyclo® series makes its gear teeth virtually unbreakable, providing an exceptionally long service life in the toughest environments.

- High Precision and Low Backlash: Sumitomo’s servo transmissions, such as the Fine Cyclo®, are engineered to achieve zero or minimal backlash, which is critical for accurate positioning in robotics and automation.

- High Efficiency: With designs that minimize friction and energy loss, many of Sumitomo’s gearboxes and servo transmissions achieve efficiencies of over 90%, which reduces energy consumption.

- High Torque Density: The advanced gearing principles allow these gearboxes to handle high torque in a compact size, enabling machine builders to create smaller, more powerful equipment.

- Shock Load Capacity: The load-sharing design of the Cyclo® series provides an unmatched ability to withstand shock loads up to 500% of the rated torque, minimizing the risk of failure in dynamic applications.

To receive a commercial offer for the supply of a Sumitomo gearbox or servo transmission, please contact our specialists. To create a request, you’ll need the following information: the specific product model, the required reduction ratio, the output speed, the motor horsepower, and the required backlash for servo applications. Providing this detailed information is crucial to ensuring the product offered is the precise one for your needs.