You can purchase Allweiler pumps and related components at competitive prices from our company. As a long-term partner with the manufacturer, we have the advantage of supplying original units and parts with minimal markup for worldwide delivery. We can also assist with the selection, sizing, and maintenance of these critical devices. A personal manager will explain the step-by-step process for purchasing an Allweiler pump.

Allweiler, a part of the CIRCOR family of brands, is a leading German manufacturer with over 150 years of experience producing a wide range of high-quality pumps. They are known for their expertise in handling challenging fluids in demanding environments and are a trusted name in the marine, oil and gas, chemical, and power generation industries.

Allweiler Pump Technologies

Allweiler specializes in both rotodynamic (centrifugal and propeller) and positive displacement pump technologies. This broad range allows them to offer solutions for nearly any fluid transfer application.

- Centrifugal Pumps: These are a versatile and common type of pump used for moving low-viscosity fluids at high flow rates. Allweiler manufactures a variety of centrifugal pumps, including single-stage, multi-stage, and self-priming models, which are used for applications like cooling water, fire fighting, and general water transfer.

- Propeller Pumps: Designed for very high flow and low head applications, propeller pumps are ideal for moving large volumes of fluid, such as in ballast systems, irrigation, and flood control.

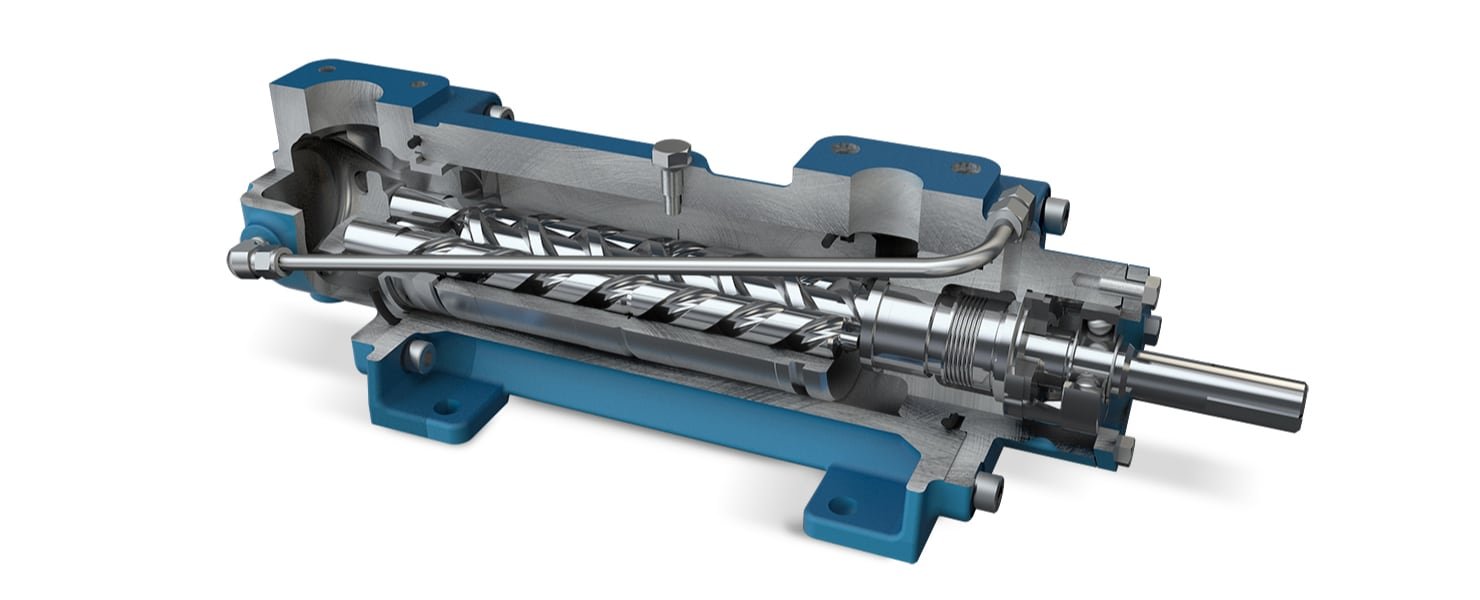

- Screw Pumps: As a leader in this technology, Allweiler offers two- and three-screw pumps that are excellent for handling a wide range of fluids, from light lubricating oils to highly viscous liquids like heavy fuel oil and tar. They provide a low-pulsation, continuous flow, making them ideal for critical industrial and marine applications.

- Progressive Cavity Pumps: These self-priming pumps use a rotating helical rotor within a stationary stator to create sealed cavities that move fluid axially. This design allows them to handle abrasive, shear-sensitive, or highly viscous fluids with high solids content without damaging the medium.

- Peristaltic Pumps: Also known as hose pumps, these are a type of positive displacement pump that provides a dry self-priming, valveless, and gasketless design, making them perfect for highly viscous, abrasive, or foaming liquids.

Key Features

Allweiler pumps are highly valued for the following characteristics:

- Rugged Reliability: The pumps are built with high-quality materials and robust designs to withstand extreme pressures, temperatures, and corrosive fluids, ensuring a long service life and minimal downtime.

- High Efficiency: Allweiler’s pumps are hydraulically optimized to ensure high efficiency, which reduces energy consumption and lowers overall operating costs.

- Versatility: With a comprehensive portfolio of different pump technologies, Allweiler offers solutions for almost any fluid and application, from low-viscosity water to thick, abrasive sludges.

- Marine Compliance: A long history in the marine industry means Allweiler pumps are designed to meet or exceed the strict standards and regulations of marine classification societies.

To receive a commercial offer for the supply of an Allweiler pump, please contact our specialists. To create a request, you’ll need the following information: the specific pump type or model number, the type of fluid to be pumped, the required flow rate, and the working pressure and temperature. Providing this detailed information is crucial to ensuring the product offered is the precise one for your needs.