MacGregor electro-hydraulic deck machinery is a workhorse in the maritime industry, representing a widely-used and robust solution for heavy-duty cargo handling and deck operations. Unlike purely electric systems that use electric motors to drive mechanical components directly, this machinery combines the power and torque of hydraulics with the convenience and efficiency of electric power.

Working Principle

The system’s operation is a hybrid of electrical and hydraulic technologies.1

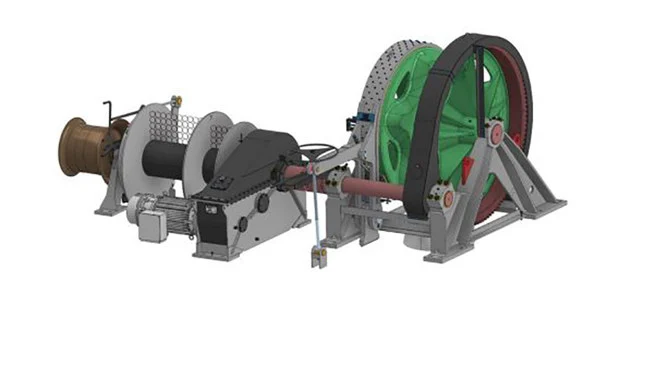

- Electric Motor: An electric motor, typically located within a self-contained unit or a central power pack, drives a hydraulic pump.

- Hydraulic Pump and Power Unit (HPU): The pump pressurizes hydraulic fluid, which is then stored in a reservoir. The HPU is the heart of the system, acting as the central source of power.2

- Hydraulic Actuation: The pressurized fluid is distributed through hoses and pipes to hydraulic motors or cylinders on the deck machinery (e.g., the hoisting winch, luffing cylinders, or slewing gear).

- Control: The flow and direction of the hydraulic fluid are precisely controlled by a system of valves, often managed by an electronic control system. This allows for fine speed and position control of the load.

This design leverages the best of both worlds: the clean, reliable power source of an electric motor and the high power density and ruggedness of a hydraulic system.

Key Types of MacGregor Electro-Hydraulic Machinery

MacGregor’s portfolio of electro-hydraulic equipment is extensive, covering a wide range of vessel types and operational needs:

- Electro-Hydraulic Cranes: These cranes are designed for bulk handling, container lifting, and general cargo operations. They are known for their high lifting capacity and robust performance, with all major movements (hoisting, luffing, and slewing) powered by hydraulic drives.

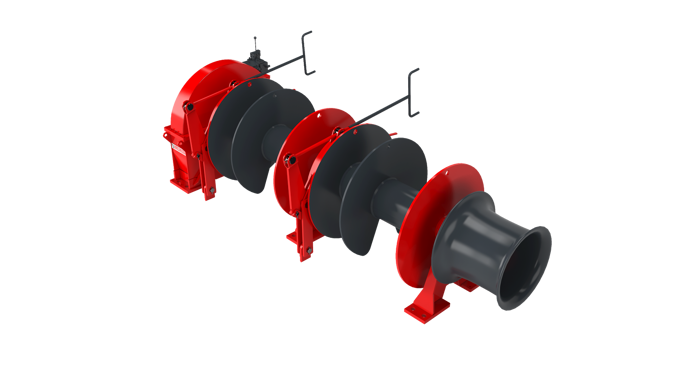

- Electro-Hydraulic Winches: Used for mooring, anchoring, and towing, these winches can handle extremely high loads and are built to withstand the harsh marine environment. The use of hydraulics allows for a compact design with immense pulling power and the ability to gracefully handle “stall” conditions.

- Hatch Cover Systems: For specific hatch cover designs, MacGregor uses electro-hydraulic systems, where a self-contained HPU provides the power to hydraulic cylinders that open and close the covers.

Advantages of Electro-Hydraulic Systems

While purely electric systems are becoming more common, electro-hydraulic systems still offer distinct benefits:

- High Power Density: Hydraulic systems can deliver a huge amount of force and torque from a relatively small and lightweight package, making them ideal for heavy lifting applications.

- Load Tolerance and Shock Resistance: Hydraulic systems are inherently robust and can absorb shocks and handle overloads without a sudden stop or damage, unlike some electric drives.

- Smooth Operation: Modern hydraulic control systems, especially closed-loop designs, provide very smooth and precise control of movement.3

- Reliability: With proper maintenance, hydraulic systems are known for their long-term reliability in demanding conditions.

Maintenance and Common Spares

Maintenance for electro-hydraulic systems requires attention to both the electrical and hydraulic components.

- Hydraulic System: Regular checks of the hydraulic oil level and quality are essential. Filters must be replaced at specified intervals to prevent contamination, which is the leading cause of hydraulic component failure. Hoses, pipes, and seals must be inspected for leaks or damage.

- Electrical System: The electric motor driving the pump, along with its control circuits and safety devices, requires standard electrical maintenance.

- Mechanical Components: Inspections of gears, bearings, and brake pads are part of a regular maintenance schedule.

Common Spares include:

- Hydraulic Filters: A full set of spare filters for the HPU.

- Seals and Gaskets: For hydraulic cylinders, valves, and pumps.4

- Hoses and Fittings: Replacement hydraulic hoses and connectors.

- Hydraulic Pumps and Motors: Spare pump and motor units or repair kits for overhauls.5

- Electrical Components: Fuses, relays, and contactors for the motor’s starter and control systems.

- Brake Pads: For winches and cranes.

MacGregor’s electro-hydraulic systems are a proven solution for marine deck machinery, offering a powerful, reliable, and durable choice for heavy-duty shipboard operations.6