Core Components of a Propeller Shaft System

A marine propeller shaft is not a single component, but a system of interconnected parts that work together to transfer power.

- Shaft Sections: The propeller shaft is often made in multiple sections to facilitate manufacturing and maintenance. These sections include:

- Thrust Shaft: The section closest to the engine/gearbox, which absorbs the forward or backward thrust generated by the propeller and transfers it to the vessel’s hull via the thrust bearing.

- Intermediate Shaft(s): Connects the thrust shaft to the stern tube shaft.

- Stern Shaft (or Tail Shaft): The final section that passes through the stern tube and connects directly to the propeller.

- Bearings: These support the shaft and allow it to rotate smoothly.

- Thrust Bearing: Takes the axial load (thrust) from the propeller.

- Intermediate Bearings: Support the weight of the intermediate shaft(s).

- Stern Tube Bearings: Located inside the stern tube, these support the tail shaft and are lubricated by oil or water.

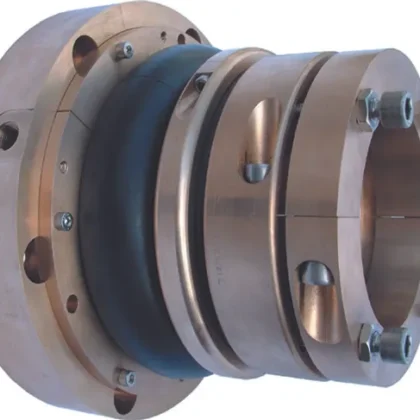

- Couplings: These are flanged connections used to join the different sections of the shaft. They must be perfectly aligned to prevent vibration and damage.

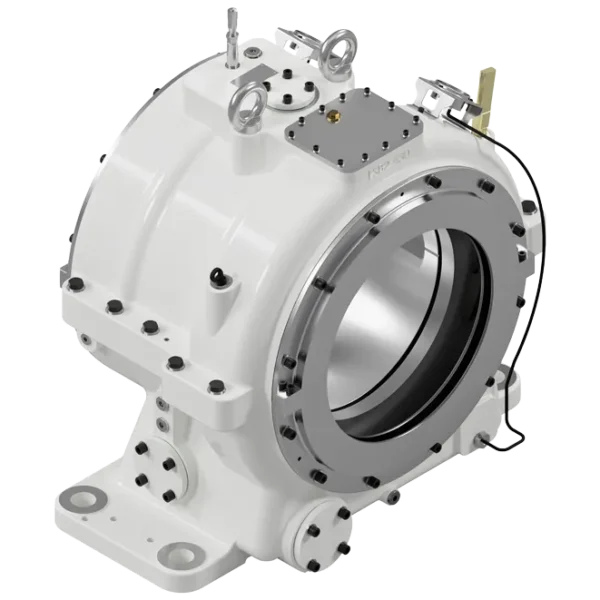

- Stern Tube & Seals: The stern tube is the watertight casing that the tail shaft passes through. It houses the stern tube bearings and sealing system.

- Propeller: The propeller itself is a key component, connected to the tail shaft with a key or a hydraulic fitting.

Key Spare Parts for Propeller Shafts

Maintaining the integrity of the shaft system is critical. A spare parts inventory typically focuses on components subject to wear, corrosion, and seal failure.

- Sealing System Spares: These are the most common and critical spares for a propeller shaft.

- Lip Seals: The flexible seals that prevent water from entering the vessel and lubricating oil from leaking out. These are subject to wear and must be replaced periodically.

- Seal Kits: Complete sets of new lip seals, O-rings, and other components for a full seal replacement.

- Inflatable Seals: Used as a standby or emergency seal for maintenance and repairs without dry-docking.

- Bearing Spares:

- Stern Tube Bearings: White metal, bronze, or composite bearings (e.g., polymer bearings) are used. Spares are essential for major overhauls.

- Thrust Bearing Pads: Pads and shoes for the thrust bearing, which can wear over time.

- Propeller Components:

- Propeller Nuts & Keys: To secure the propeller to the shaft.

- Propeller Hub Kits: Parts for the hub, especially for controllable-pitch propellers.

- Corrosion Protection:

- Sacrificial Anodes: Zinc or aluminum anodes attached to the shaft to prevent galvanic corrosion. These must be replaced regularly.

- Gaskets and O-rings: For couplings, stern tubes, and other flanged connections.

- Shaft Sleeves: Worn tail shafts can be repaired by fitting a new sleeve, so a spare is sometimes kept on board.

Maintenance and Importance

Proper maintenance is paramount for the propeller shaft system.

- Alignment: The entire shaft line must be perfectly aligned to prevent excessive vibration and bearing wear.

- Lubrication: Stern tube bearings require a constant supply of oil or water for lubrication. Monitoring this system is vital.

- Inspection: Regular inspections of the seals, bearings, and sacrificial anodes are essential.

- Dry Docking: Propeller shaft withdrawal for full inspection and service is a major procedure typically performed during dry-docking.

A well-maintained propeller shaft with a proper stock of spare parts ensures the safe and efficient transfer of power, preventing catastrophic failures at sea.

We offer an extensive range of marine engine brands and their associated spare parts, providing comprehensive solutions for both main propulsion and auxiliary power needs across diverse vessel types. Our supply capability covers various generations and models, ensuring support for a wide array of marine applications.

Featured Brands and Engine Series/Models:

SULZER:

- Two-Stroke Engines:

- RD/RND Series: RD68, RND76, RND76M, RND90, RND90M (Classic large-bore, low-speed engines, still in operation).

- RLA/RLB Series: RLA(B)56, RLA(B)66, RLA(B)76, RLB90 (Developed two-stroke designs).

- RTA/RT-Flex Series: RTA38, RTA48(T), RTA52, RTA58, RTA62, RTA72, RTA76, RTA84, RTA84M, RTA84C, RTA96 (Modern, fuel-efficient, electronically controlled two-stroke engines).

- Four-Stroke Engines:

- Z Series: ZL40/48, 16ZAV40S (Medium-speed engines).

- RF Series: RF44, RF56 (Often used for auxiliary power or generator sets).

- TAD Series: TAD36, TAD48 (For specific applications).

MAN (including pre and post-MAN B&W models):

- Two-Stroke Engines (KZ, KSZ, K, L, S, MC/MC-C, ME/ME-C): 40/54A, 52/90N, 57/80C, KZ57/80F, KSZ70/125, KSZ78/155, 90/160A, 52/55L, 58/64, 90/190C, L60/105E, 70/120E, 70/125C, L, KSZ78/155A, KSZ70/125B, L52/55A, 40/45 (A broad spectrum covering main propulsion and auxiliary engines).

B&W (Burmeister & Wain – prior to MAN B&W merger):

- MC/MCE Series: L35MC, L60MC, L80MC, L55GFCA, L80GFCA, L80GB, 74VT2BF, K62EF, K74EF, K84EF, K45GFC, K67GFK, K80GFK, K90GFS, 45HU, L70MC (Various generations of two-stroke diesel engines).

- MC-C/ME-C Series: L50MC, S60MC, S70MC, K80MC, S80MC, K90MC-C, L67GFCA, L90GB (Electronically controlled and conventional two-stroke engines).

- VT2BF/EF Series: 50VT2BF, 62VT2BF, K84EF (Older models still in service).

MITSUBISHI:

- UEC/UET Series: UEC37L/LA/LS, UEC45HA, UEC60L/LA/LS, UEC45L/LA/LS, UET45/75C, UEC52/125H, UEC52L/LA/LS, UET45/80D, UEC52/90D, UEC(T)52/105D, UEC45/115H, UEC37/88H, UEC37H (Mitsubishi’s proprietary two-stroke and some four-stroke engine series).

PIELSTICK:

- PA Series: PA6, PC3, PC2-2, IHI PC2-5, PC4, PC2-6, PC4-2L, PC4-570, PA5 (High-speed, compact four-stroke engines, commonly used for generator sets or auxiliary propulsion).

AKASAKA:

- UET/UEC/DM/AH Series: UET45/80D, UEC52/105D, DM51SS, UEC 60/150H, UEC 60H, A31, A34, A37, A41, AH27, AH28, AH30, AH36, AH38, AH40, DM30, DM36, DM38, DM46, DM47 (A prevalent engine brand, particularly in Japanese-built vessels).

DEUTZ:

- RBV/TBD/BVM Series: RBV8M358, RBV8M540, RBV16M640, TBD620L6, BVM350, BVM540, BF6M716 (Various four-stroke medium- and high-speed diesel engines for auxiliary and smaller main propulsion applications).

HANSHIN:

- EL/LH/LU/LUN/LUD/LUS Series: EL30, EL32, EL35, EL40, EL44, LH28RG, LH31G, LU28(A,R,G), LU32, LU35, LU38, LU46(A), LU50, LU54, LUN28, LUN30, LUD32, LUD35, LUS38 (Another significant engine brand commonly found in Japanese vessels).

NIIGATA:

- MG/M Series: MG40X(EX), M34X, 6M28BF, TM31X (Medium-speed diesel engines, typically used in small and medium-sized vessels).

MAK:

- M/MU/AK/AKM Series: M332, M453AK, MU551AK, MU552AK, M601, MU452AK, 451AK, 6M453AK, 9M453C, 6M601C, 8M601 (Medium-speed four-stroke engines, widely used in various marine applications).

WARTSILA:

- 20/22/26/32/38/46/GD/TKR Series: 22, 32, 31, 26, 20S, 28, 38, 46, 32GD, 46GD, 14, TKR22, HFR-V32, NOHAB (Wärtsilä’s broad portfolio of medium- and high-speed diesel engines for main propulsion, auxiliary, and generator sets).

DAIHATSU:

- PS/PKT/DS/DL/DK/PL Series: PS-18, PS-22, PS-20, PS-26, PS-30, PKT-14, PKT-16, PKTD-16, DS-18, DS-22, DS-26, DS-28, DS-32, DL-14, DL-16, DL-19, DL-20, DL-22, DL-24, DL-26, DK-20, PL-24 (Compact and reliable engines primarily used for auxiliary power and generator sets).

CUMMINS:

- BT/CT/NT/KTA/QSK/QSM Series: 4BT3.9, 6BT(A)5.9, 6CT8.3, NT(A)855, N14, KTA19, KTA38, KTA50, QSK19, QSM11 (Robust and durable engines for marine auxiliary power, generator sets, and some smaller main propulsion applications).

CATERPILLAR:

- 3000/3100/3300/3400/3500/3600 Series & C Series: 3054, 3056, 3066, 3106, 3126, 3306, 3406, 3408, 3412, 3508, 3512, 3516, 3606, 3608, 3612, 3616, 3618, C1.5, C2.2, C7, C9, C10, C12, C15, C16, C18, C30, C32 (Reliable and widely used engines across a vast range of main propulsion, auxiliary, and generator set applications).

SCANIA:

- DI Series: DI 09, DI 13, DI 16 (High-performance diesel engines designed for marine applications, typically used as auxiliary and smaller main propulsion engines).